Ansaam Leading Industrial Company plans to develop a modern plastic recycling facility on a 5,000 m² industrial site. This facility will convert post-consumer and industrial plastic waste into high-quality recycled plastic pellets, promoting both environmental sustainability and economic development.

- Capacity: 500–800 tons/month initially, scalable to 20,000+ tons/year. Industry benchmarks show facilities of this scale can reach 20,000+ tons/year under optimal

conditions

- Technology: End-to-end recycling line: shredding, washing, drying, extrusion, and pelletizing.

- Jobs Created: 17 direct roles at launch, with room for growth.

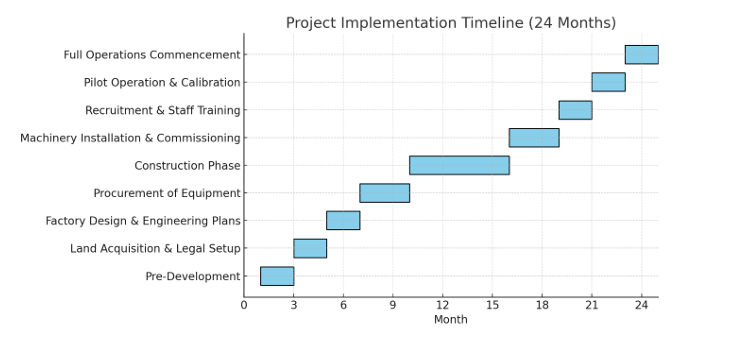

- Timeline: 24-month development plan, from preliminary approvals to full production. Construction and equipment installation will be completed by month 18, allowing for pilot runs and calibration before commercial operations commence by the end of year 2.

- Sustainability Focus: The project aligns with circular economy principles and Saudi Arabia’s Vision 2030 goals. It will divert significant plastic waste from landfills, reducing pollution and conserving resources. Recycling plastics uses far less energy and emits significantly fewer greenhouse gases than producing virgin plastic, making this venture environmentally and socially responsible.

This project transforms waste into value, provides employment, and supports national sustainability goals.

Project Name: Ansaam Plastic Recycling Factory

Company: Ansaam Leading Industrial Company

Location: 5,000 m² industrial-zoned land

Objective: Recycle plastic waste into high-value pellets to reduce environmental impact and reliance on virgin plastics.

Strategic Objectives:

- Environmental: Contribute to 40% recycling target by 2040.

- Economic: Generate revenue from pellet sales and support domestic industry.

- Social: Promote environmental responsibility and support local waste collection networks.

Facility Layout: Designed for optimal material flow, scalability, and operational efficiency.

Market Demand: With GCC per capita plastic use at 33 kg, growing demand for recycled

materials presents a clear market opportunity.

Startup Throughput: ~500 tons/month (6,000 TPA)

Future Capacity: Up to 1,000 tons/month (12,000 TPA)

Designed for flexible processing of PET, HDPE, LDPE, and PP. Capacity can expand with additional shifts or lines.

To achieve a full end-to-end recycling process, the factory will be outfitted with a complete set of specialized equipment covering each stage of plastic recycling. The major equipment and machinery components required are:

All the machinery will be laid out with safety and efficiency in mind. Safety features (emergency stop mechanisms, fire suppression near extrusion, ventilation for any fumes) will be implemented. The equipment selected will be robust and reputable, with local or easily accessible maintenance support. This ensures high uptime and longevity of the production line.

By deploying this full suite of equipment, the Ansaam factory will cover all stages from and cleaning of waste to producing final recycled pellets. These stages – sorting, cleaning, size reduction, melting, and pelletizing – are standard in advanced recycling operations. The chosen technology ensures that the output pellets will be of consistent quality, suitable for use in manufacturing new plastic products (e.g. bottles, pipes, film, etc.), thereby closing the loop in the plastic supply chain.

Supporting Systems: Conveyors, bagging stations, silos, control panels, lab and safety equipment.

To efficiently operate the recycling facility, Ansaam will implement a lean but effective staffing plan, scaling human resources to match the 5,000 m² plant’s capacity. Initially, 17 personnel are planned, organized into operations, maintenance, quality, and administration. Table 1 below outlines the roles and headcount:

| Position | Headcount | Role/Responsibilities |

|---|---|---|

| Factory Manager | 1 | Senior manager overseeing overall plant operations, production targets, and compliance. Acts as the project leader interfacing with company management and regulators. |

| Shift Supervisors | 2 | Supervisors (one per shift) managing daily floor operations, coordinating staff, and ensuring safety and procedures are followed. Each shift supervisor oversees the production line during their shift. |

| Machine Operators | 4 | Operate and monitor the recycling machinery: shredders, wash line, extruder, and pelletizer. (2 operators per shift to cover critical stations.) They control equipment settings, feed materials, and respond to process alarms. |

| Maintenance Technicians | 2 | Responsible for equipment upkeep – performing routine maintenance, troubleshooting breakdowns, and coordinating any mechanical/electrical repairs to minimize downtime. |

| Quality Control Inspectors | 2 | Test and inspect materials at various stages: check incoming waste batches (for contaminants), monitor wash water quality, and especially test final pellets (for consistency, moisture, MFI, etc.). Ensure output meets quality specs and maintain documentation for certifications. |

| Administrative Staff | 2 | Handle office management, record-keeping, procurement of supplies, coordination of logistics (shipments of raw waste in and pellet product out), and general administrative tasks. Also assist with bookkeeping and regulatory reporting. |

| General Laborers | 4 | Provide manual labor support such as feeding conveyors, baling scrap materials (like separated trash or metal contaminants), cleaning equipment, loading/unloading materials, and other general tasks to keep operations running smoothly. They may also assist in manual sorting of waste on the pre-sorting conveyor. |

Table 1: Initial Staffing Plan (17 total staff).

Training and Development: Each staff member will undergo training prior to plant start-up

Operations: Two-shift structure with comprehensive safety and operations training. Staffing will scale with production.

Ansaam has developed a detailed implementation schedule to ensure the project stays on track and is delivered within 24 months (2 years). The timeline is broken into phases, each with specific tasks and milestones. Figure 1 below provides a visual Gantt-chart overview of the project timeline, and the subsequent text outlines each phase:

This initial phase includes all preparatory work before physical execution. Key activities:

In this phase, the focus is on

securing all legal rights and permits:

Once approvals are in hand, detailed design work proceeds:

With designs ready, ordering long lead items begins:

Physical construction on site takes place:

As equipment arrives (likely during months 15–16), installation begins:

While some key staff are already hired by this time, the bulk of hiring is completed here:

This is the ramp-up period where the plant operates on a trial basis:

The plant transitions to continuous commercial operations:

Throughout the implementation, robust project management practices will be applied: progress will be tracked against this timeline, with buffer time built into critical path items when possible. The timeline also assumes no major delays in permits or procurement; proactive risk mitigation (like starting permit processes early and choosing reliable suppliers) helps keep it on schedule. Milestones such as “Building Ready”, “Equipment Installed”, “Trial Run Completed” will be used to measure progress.

By the end of the 24-month implementation period, the expected key outputs are:

This timeline and plan ensure that the Ansaam Plastic Recycling Factory is delivered on time and on budget, ready to fulfil its intended role in the market and community.

This proposal has outlined a comprehensive plan to establish the Ansaam Plastic Recycling Factory as a pioneering project in the region’s circular economy landscape. With a professional execution strategy, realistic financial planning, and deep commitment to environmental sustainability, the project is well-positioned for success. It promises to transform the way plastic waste is handled – from a disposal problem into an economic resource – and in doing so, deliver benefits to the company, the community, and the planet.

By implementing this plan, Ansaam will not only create a profitable new business unit but also demonstrate leadership in sustainable industrial development. The factory will serve as a tangible example that “green” initiatives can also be financially rewarding, effectively bridging the gap between profitability and responsibility. We anticipate strong support and interest from stakeholders including government bodies (keen on waste management solutions), customers (seeking recycled materials for their own sustainability goals), and the public (who will see direct impact through cleaner environment and new job opportunities).

With all the pieces in place – executive commitment, technical know-how, market demand, and alignment with strategic sustainability objectives – the Ansaam Plastic Recycling Factory project is ready to move from concept to reality. We invite stakeholders and partners to join us in this endeavor as we embark on building a cleaner, more circular future.